Solutions That Bringing Superior Technology and Innovations Together Reach All Around Turkey With Tekniker DK Freeze Dryer!

Technician DK Freeze Dryer manufactures new generation freeze dryers for all capacities from small companies to large facilities. Our company, which has established a system that will fully meet the needs by analyzing the user needs in the most accurate way, works with expert teams in the design, production and

MORE INFOFreeze drying is a state-of-the-art system that has begun to gain a place in many different sectors from food to pharmaceuticals, from floriculture to pet food and dairy industries. As Technician DK Freeze Dryer, we guarantee testing for every device we produce in the freeze-drying sector, and we can set

DETAILIt is a gentle process that preserves the original shape, color, taste and nutritional value of the product. Freeze drying is an effective method to extend the shelf life and has two important features: 1. There is no air in the environment during the process. 2. Drying takes place at a

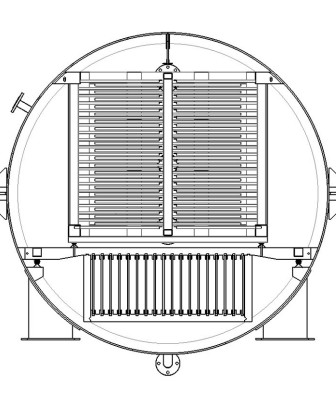

DETAILIt is designed for continuous high-volume processing of foods such as fruit-vegetables, tea-coffee, meat and seafood. It is fully automatic and requires a minimum number of personnel for continuous operation. All motion and process parameters are carefully controlled, monitored and recorded. The cabinet is in the shape of a cylindrical chamber designed

DETAIL

Freeze dryers are a device that can be used by many different businesses, from small-scale enterprises to full-scale large facilities. Freeze dryer, which has become an indispensable part of pharmaceutical, food and bio-chemistry sectors, can be in various capacities from three shelves to 80 shelves. Pricing in freeze dryers is one of the curious issues. Here, in order to answer the price question, it is necessary to know the capacity expected from the device. How many shelves are desired to be inside, we also consider these features in pricing. The sector and product in which the device will be used, the freeze-drying

Freeze dryers are very easy to use devices. The device, which generally consists of a cylindrical main body, has an input and output area and a control panel. It has product placement bands inside, just like an oven. The products to be freeze dried are placed on these bands. Then the doors must be closed and the system must be adjusted according to the properties of the product to be dried. After the necessary arrangements are made from the panel, the process starts and hundreds or even thousands of products are freeze-dried at the same time. Thanks to the freeze-drying method,

Freeze drying is a dehydrating process to increase the strength of products. The product is frozen, then placed under a vacuum to remove all water. In this process, the direct passage of water from solid to steam is ensured without exposing it to high temperature. Since no extra additives are added to the product during this process, the quality of the product and the nutritional value of the food are provided at a high rate.

You Can Contact Us For The Most Efficient Designs In Freeze Drying

Copyright © 2020 - 2025 Saruhan Web Ajans | Tüm Hakları Saklıdır.